From thermoforming to 3D printing

Manufacturing expertise from a single source

We bring the latest technologies together in one place and are your reliable full-service partner—from the initial idea to the finished product. Whether thermoforming, injection molding, milling, textile processing, 3D printing, or CAD development, PARAT produces high-quality case components that are assembled in our production to create functional and durable solutions. This ensures maximum quality and efficient processes—everything from a single source.

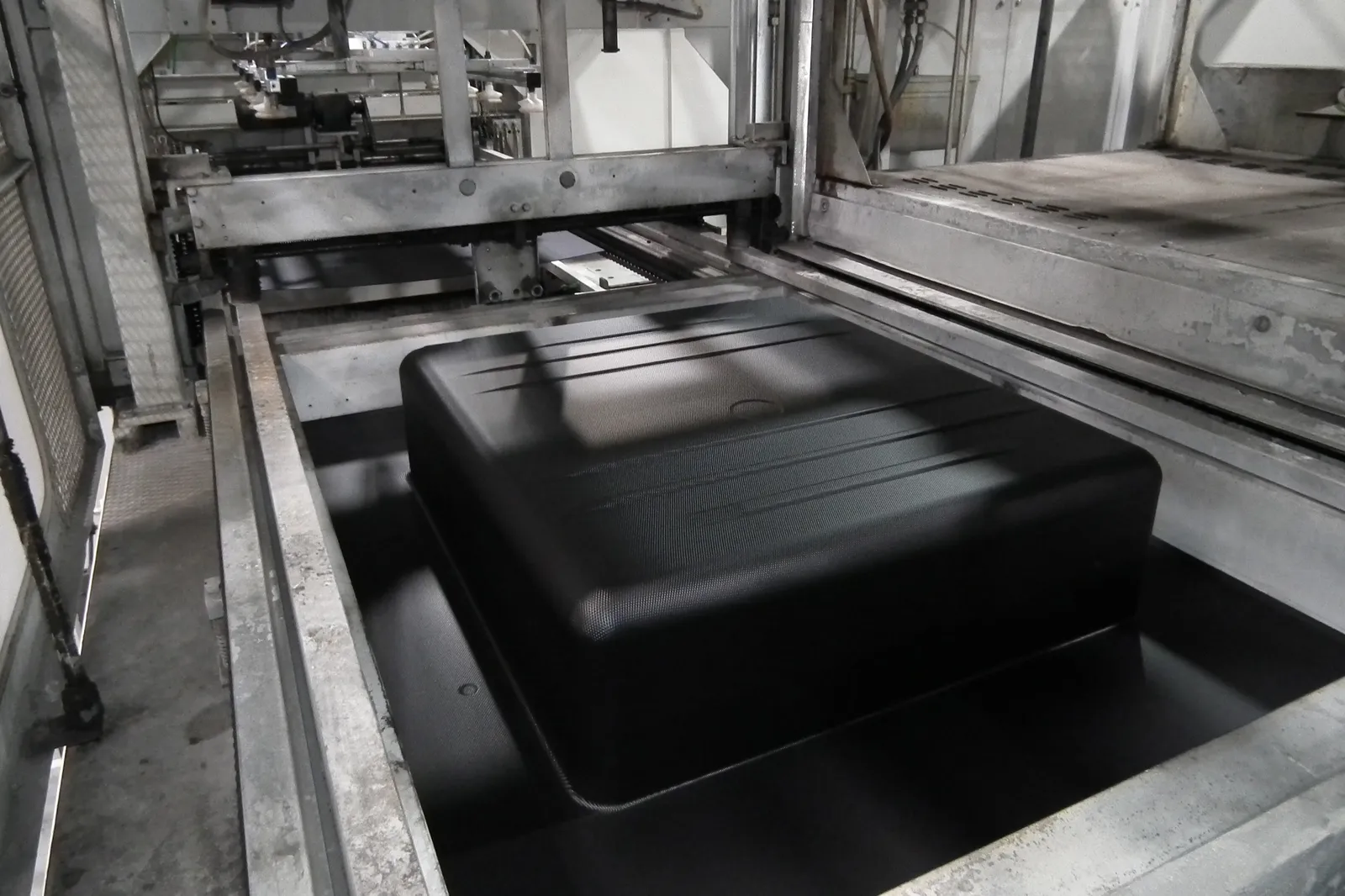

Thermoforming

Robust cases, flexibly shaped

For the production of our robust case shells, we rely on proven thermoforming, also known as vacuum forming. In this process, plastic sheets are first evenly heated and then precisely shaped into the desired form. The method allows flexible customizations in terms of size, wall thickness, or case contour. Compared to injection molding, thermoforming offers lower tooling and setup costs, especially for medium to small production runs.

Injection molding

Precise cases, manufactured in detail

For complex shapes and the highest precision, we use injection molding. In this method, plastic granules are heated, melted, and injected under high pressure into a mold. This process allows for case components with fine details, uniform wall thicknesses, and intricate contours. Compared to thermoforming, it is also possible to achieve particularly thick walls for maximum durability. Especially for large production runs, the method ensures efficiency, reproducibility, and consistently high quality.

Milling

CNC-engineered for perfect results

Using advanced CNC milling technology, we process plastic components for our cases with the highest accuracy. This method allows for precise cutouts, guides, and contours, ensuring easy assembly and reliable functionality. At the same time, the precise surface machining of the milled parts guarantees an exact fit and a durable connection between the case components.

Textile processing

Precision in every stitch

The series production of our tool bags is carried out with meticulous handcrafting by experienced seamstresses working on modern sewing machines. This ensures consistently high quality and efficiency. For prototypes and customized special solutions, our in-house development department and manufactory take center stage. Here, the artisanal skills of our employees come fully into play: rivets and eyelets are placed precisely, holes are accurately punched, and various textiles and plastics are carefully sewn together. The result is durable bags with a quality you can both see and feel.

CAD

When every detail counts

At PARAT, quality starts with digital precision. Using state-of-the-art CAD systems, case shells and components are designed virtually with exact accuracy – from wall thickness and contours to complex details. This allows adjustments and optimizations to be evaluated early, before a physical prototype is created. Our in-house CAD expertise enables short development cycles, high planning accuracy, and precisely fitting solutions that seamlessly transition into production.

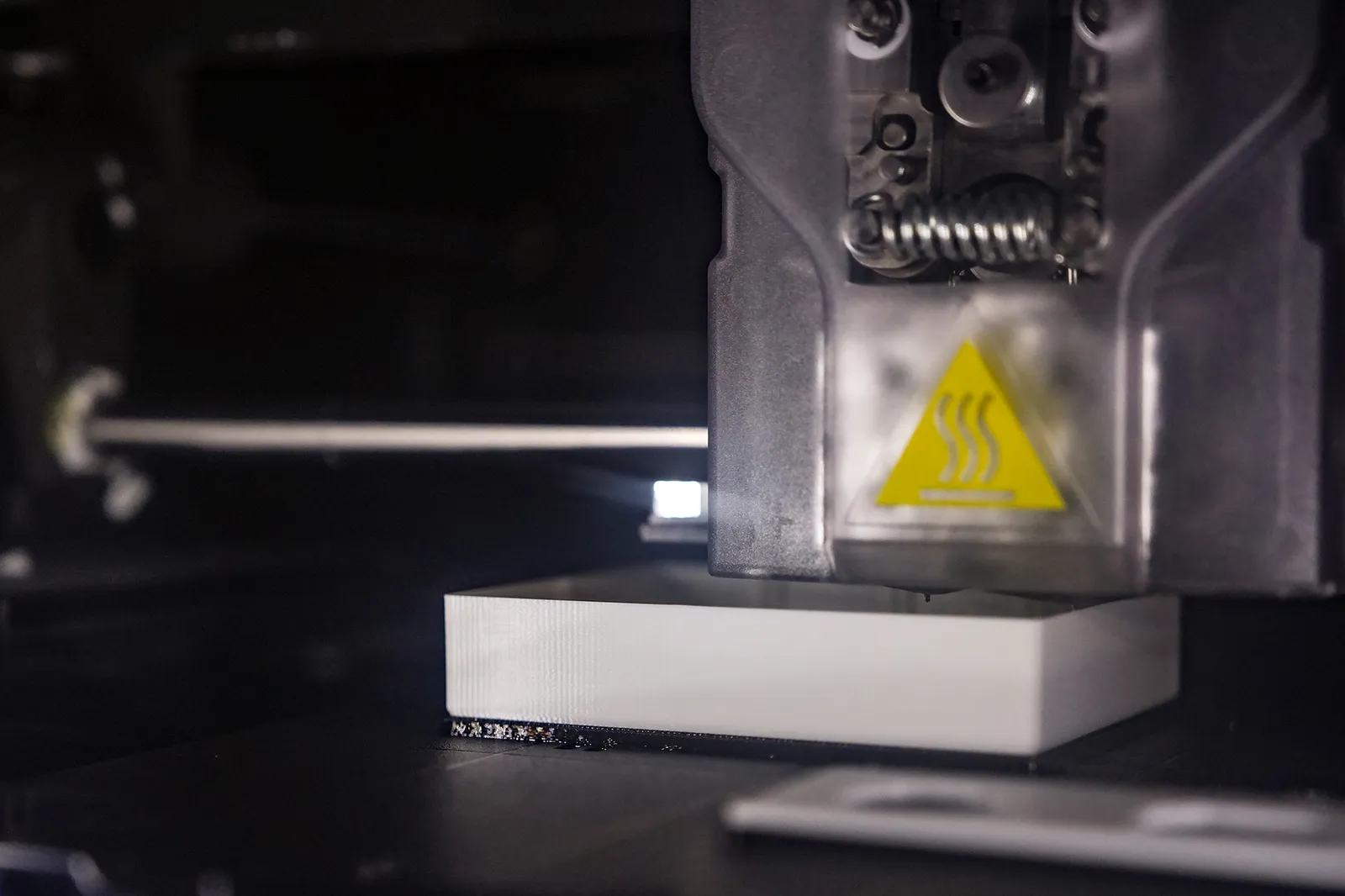

3D printing

From idea to tangible model

We use 3D printing technology to create samples and prototypes that support the further development process. With state-of-the-art 3D printing, we produce precise models that serve as the foundation for subsequent product development. The plastic is built up layer by layer, allowing shapes, proportions, and functions to be evaluated early on. This makes it possible to implement individual adjustments efficiently before series production. Our 3D printing capabilities enable us to visualize designs with the customer, compare variants, and significantly shorten development times.

Assembly

Everything from a single source

As a full-service partner, we maintain control over every step, from design to final production. Adjustments to components, positioning, and assembly can be implemented and tested directly, allowing us to respond flexibly to changes during the development phase. Even in series production, individual work steps are still carried out manually. This ensures that our tool bags and cases are durable, reliable, and of consistently high quality in every aspect.

Solutions

An overview

Interior Design

The inner values: efficiency and order

Efficient storage is essential, and the right interior design can make all the difference…

Fields of application

What we are good at

PARAT offers customized storage solutions for a wide range of industries and applications…

Organizer systems

Fits, no wobbles, and plenty of space

Organization is key to maximizing efficiency. That's why we offer a flexible system that …

Electrification

Always ready to start

Digitalization has become a crucial aspect in all industries. At PARAT, we address this g…

Transport systems

Mobile comfort

When it comes to storage, mobility is key. That's why we offer a range of versatile trans…

Locking systems

Better safe than sorry

Security: an essential aspect to consider when dealing with high-quality products, goods,…

Materials

Material that provides options

We place great value on versatility and quality, which is why we utilize a wide range of …

Storage options

Type follows requirement

We understand that every individual has different storage requirements, and that's why we…

Branding

My Case

Your brand should present what it is made of. PARAT offers you different branding solutio…